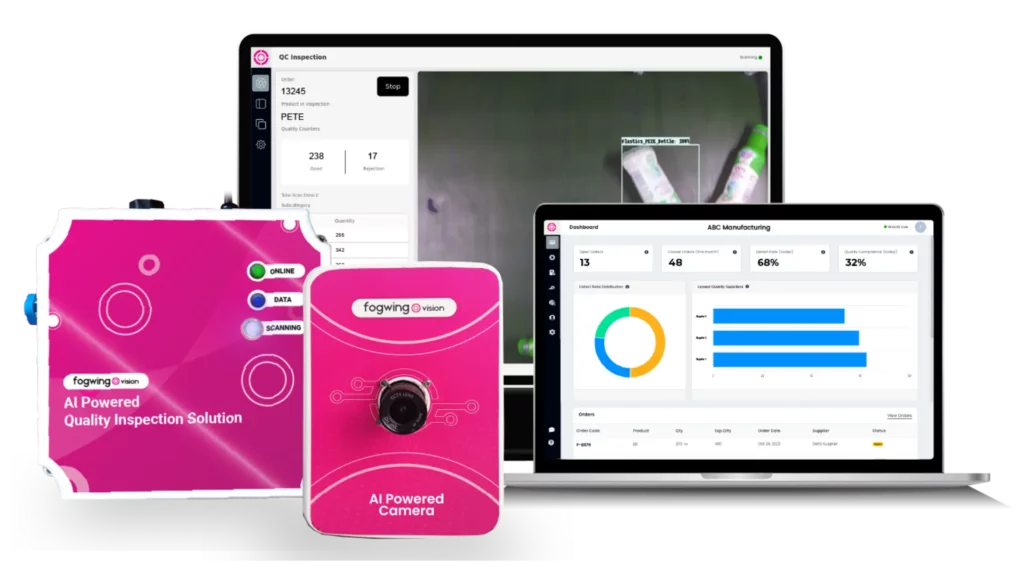

Defect Detection Software

AI-Powered Defect Detection Software for Zero-Defect Manufacturing

Fogwing Automated Defect Detection Software uses advanced AI and computer vision to automate visual inspection across manufacturing lines, eliminating manual errors and enabling real-time quality decisions.

Detect defects faster, reduce quality losses, and ensure consistent product quality with the AI‑Powered Fogwing Vision Platform.

Over 10,000+ Manufacturing Operators trust Fogwing for Productive Day

Fogwing Defect Detection Software for Quality Inspection

Fogwing Defect Detection Software is an AI-driven visual inspection solution built on the Fogwing Vision Platform.

Fogwing offers a comprehensive set of AI-powered capabilities designed to automate, standardize, and scale visual defect detection for quality inspection across the manufacturing value chain.

Built on the Fogwing Vision Platform, these capabilities ensure consistent quality checks for raw materials, in-process items, finished goods, and supplier shipments.

Defect Detection by Inspection Stage

Fogwing Automated Defect Detection Software enables end-to-end visual quality inspection across every critical stage of manufacturing.

Supplier Goods Inspection

Fogwing Vision AI detects surface defects, dimensional deviations, damages, contamination, missing parts, incorrect labeling, and packaging issues in raw materials and bought-out components.

Automated inspection ensures objective, repeatable quality checks, eliminating dependency on manual sampling.

By capturing defect images, supplier-wise defect trends, and acceptance or rejection data, Fogwing helps quality teams benchmark suppliers, enforce quality standards, and drive supplier quality improvement programs.

Production Process Quality Inspection

Using edge-based AI vision, Fogwing inspects intermediate products, assemblies, and sub-components for defects such as misalignment, missing components, surface anomalies, improper assembly, and process deviations.

Instant alerts and automated rejection mechanisms allow operators to take corrective action immediately.

This closed-loop inspection approach helps manufacturers stabilize processes, improve first-pass yield, and prevent defect propagation across subsequent stages.

Finished Goods & Packaging Inspection

Fogwing automates finished goods and packaging inspection using advanced computer vision and deep learning models.

Fogwing detects cosmetic defects, functional anomalies, incorrect labeling, barcode or QR code mismatches, seal integrity issues, and packaging damages. AI-powered inspection ensures brand protection, regulatory compliance, and consistent customer experience.

Comprehensive inspection data, images, and reports support audit readiness, traceability, and continuous improvement in finished goods quality.

Defect Reports and Insights

Fogwing automatically aggregates automatically defect data from incoming inspections and builds supplier-wise quality scorecards. These scorecards track key metrics, including defect rate, defect type distribution, rejection trends, recurring issues, and compliance history.

Quality and procurement teams can use Fogwing:

- Compare supplier performance objectively using data-driven metrics

- Identify high-risk suppliers and recurring defect patterns

- Enforce incoming quality agreements and SLAs

- Support supplier audits and corrective action programs

- Drive continuous supplier quality improvement

Fogwing Defect Detection Software Serves

Automotive

Detection of surface defects, dimensional issues, and assembly errors in parts and sub-assemblies.

Electronics

Inspection of PCBs, solder joints, connectors, and micro-components with high precision.

Pharma & Medical

Visual inspection for packaging integrity, labeling accuracy, and compliance-critical defects.

Food & Beverage

Identification of contamination, packaging defects, sealing issues, and visual non-conformities.

Plastics & Packaging

Surface defect detection, such as cracks, dents, scratches, and deformities.

Recycle & Waste

Automated materials identification, classification, and sorting

Values Delivered by Fogwing Defect Detection Software

01.

Built on the AI-Powered Platform

Fogwing is powered by an advanced AI vision platform purpose-built for industrial environments. Fogwing uses deep learning models that adapt to variations in product appearance and process conditions.

02.

End-to-End Quality Coverage

Fogwing enables visual inspection across incoming supplier goods, in-process production, and finished goods, ensuring quality consistency throughout the manufacturing lifecycle.

03.

Lower Total Cost of Ownership

With pre-built AI models, low-code configuration, and scalable architecture, Fogwing reduces deployment time and minimizes long-term operational costs.

04.

High Accuracy with Continuous Learning

Fogwing’s AI models continuously learn from new data, reducing false positives and improving defect detection accuracy over time.

05.

Scalable Across Operations

Standardize inspection processes across multiple production lines, factories, and supplier locations with centralized governance and analytics.

FAQs about Defect Detection Software

Fogwing Defect Detection Software is an AI-driven visual inspection solution built on the Fogwing Vision Platform. It automatically identifies surface defects, dimensional deviations, missing components, and visual anomalies using advanced deep learning and computer vision algorithms. Designed for modern manufacturing, Fogwing enables continuous inspection with high accuracy and minimal human intervention.

Fogwing can detect surface defects, scratches, dents, cracks, color variations, missing components, dimensional issues, and visual anomalies.

Yes. Fogwing’s edge AI architecture enables real-time inspection at production-line speeds.

No. Fogwing supports rapid model training with limited data and improves accuracy over time through continuous learning.

Fogwing integrates easily with MES, ERP, CMMS, PLCs, and quality management systems.

More Questions about Fogwing Defect Detection Software?

You may have more questions. If so, you may write to our team; we are happy to answer all your questions.