AI-powered Quality Inspection Software

Automated Quality Inspection for Smart Manufacturing

Fogwing Vision is an AI-powered Quality Inspection Software that enforces intelligent visual inspection through advanced AI computing to detect finished goods’ defects and quality parameters before delivery and accept supplier materials. Enhance your productivity and quality compliance with precision.

AI-Powered Automated Quality Inspection

New way of conducting Quality Inspection for higher accuracy and consistency.

Empower Your Team with Quality Inspection Software

AI-powered visual quality inspection is a software application for manufacturing that ensures faster, automated quality checks with more accurate defect detection, reducing human error and meeting quality compliances consistently. This approach enhances product consistency, boosts operational efficiency, and lowers inspection costs.

With real-time dashboard and defect metrics, manufacturers can maintain high quality standards, minimize waste, and achieve greater scalability, ultimately improving customer satisfaction and competitive advantage.

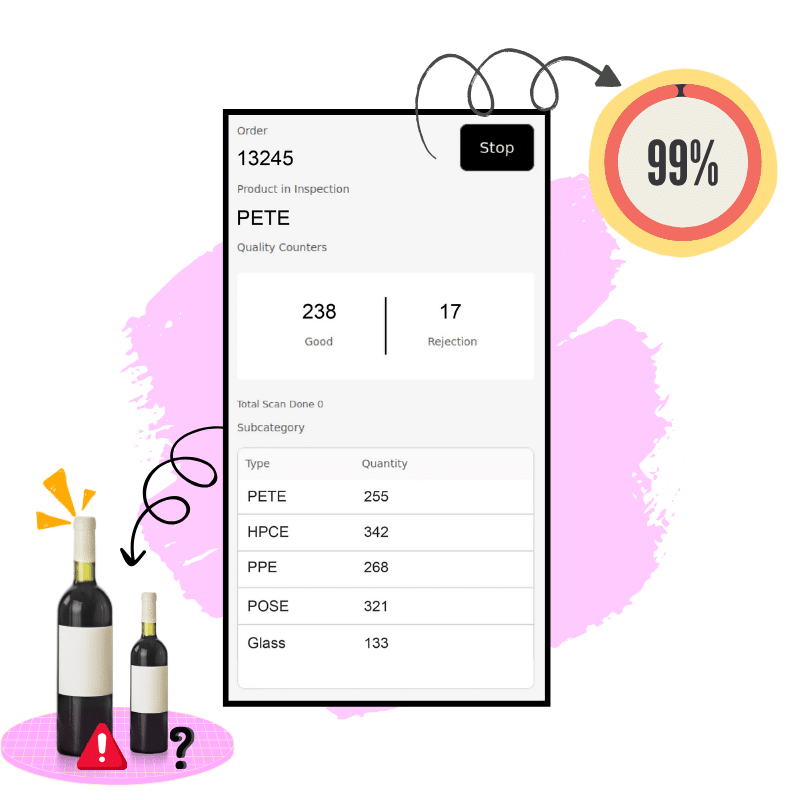

Boost up to 99% Accuracy in Quality Checks and Defect Identifications

Are you ready to revolutionize your quality checks and elevate your standards by an astounding 99%? Fogwing Vision is here to empower your business with cutting-edge solutions that redefine the way you ensure quality. It is time to adopt newer technologies to identify the deeper defect rating.

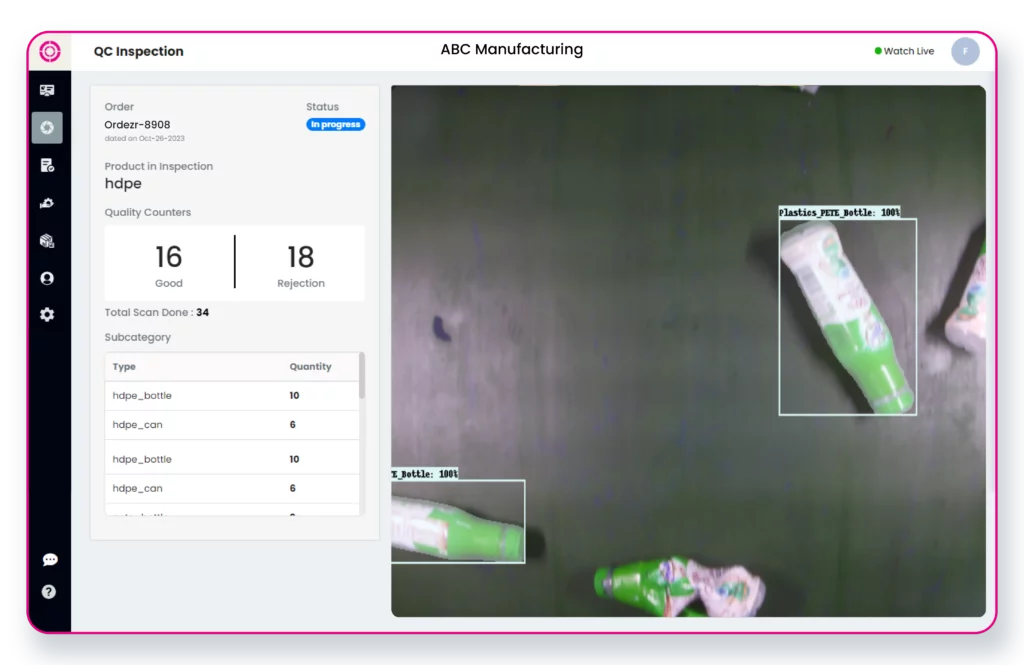

Remote Access to Quality Inspection data for Higher Visibility

Fogwing Vision solution offers seamless remote access to your quality inspection data, empowering your team with real-time insights from anywhere in the world. Experience the convenience of monitoring and analyzing quality metrics at your fingertips, ensuring that critical decisions are made promptly.

With this remote access capability, collaboration becomes more agile, and your operations gains the flexibility to adapt to evolving quality standards.

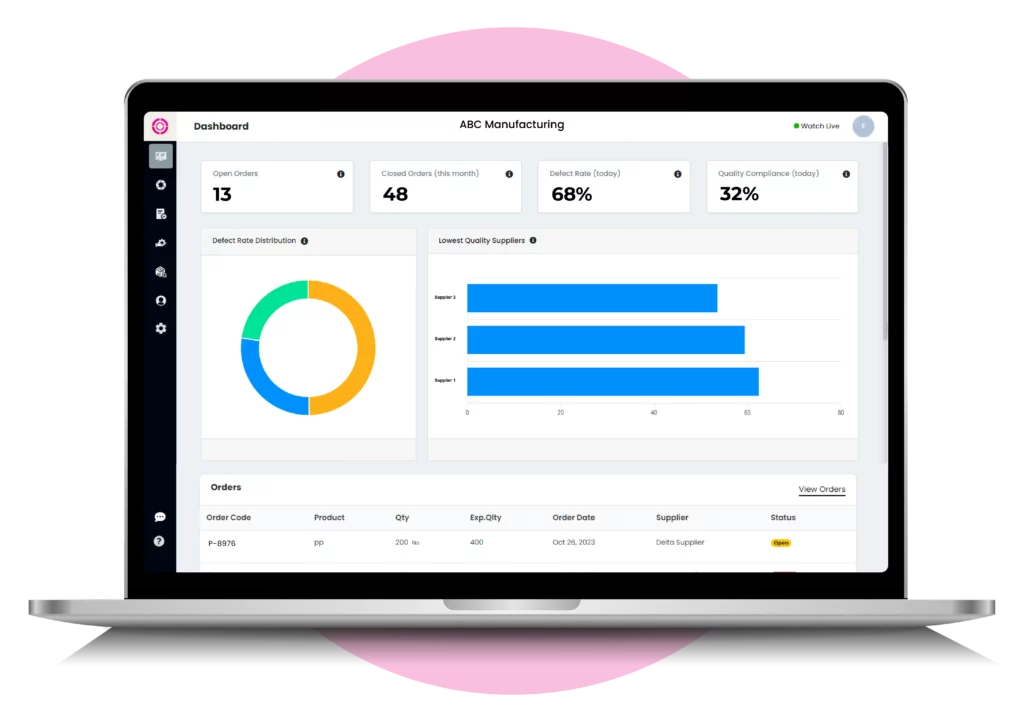

Quality Metrics Dashboard for Plant Level Visibility

This intuitive dashboard consolidates comprehensive quality inspection metrics into a single, easy-to-navigate interface, offering real-time insights into your plant’s performance. Monitor key quality indicators, track trends, and identify defect trends.

Our dashboard provides plant-level visibility in quality, empowering decision-makers to make informed choices promptly, fostering a proactive approach to quality management.

Fogwing Vision Edge AI Kit

Fogwing Vision Edge AI devices have an industrial camera capable of taking 30 fps images and an AI processor with 40 TOPS GPU performance. This can be mounted on the conveyor belts for scanning high-speed production.

Custom Machine Vision Model

For higher accuracy and perfection, every devices loaded with custom ML model trained according to customer requirements.

Vision Application Loaded

Fogwing vision devices come with Ubuntu OS, Vision Device Application, Cloud Connector and LED Touch Display for Operators inputs.

Wired communication

Fogwing Edge devices are capable of communicate to Fogwing Cloud directly through WIRED and WIFI network but preferred WIRED.

Why AI-powered Quality Inspection?

01.

Improved Accuracy

AI-powered quality inspection ensures precise defect detection by consistently analyzing visual data, significantly reducing human errors and overlooking defects, thus maintaining superior product quality throughout manufacturing.

02.

Real-Time Defect Detection

AI-powered systems instantly identify defects during production, enabling immediate corrective actions. This minimizes downtime, prevents defective output, and ensures a continuous flow of high-quality products.

03.

Consistency in Quality

AI-powered inspection maintains uniform quality standards by applying the same evaluation criteria across all products, eliminating subjective judgments and variability, and ensuring every item meets predefined specifications reliably.

04.

Faster Inspection Speed

High-performance GPU-based computing systems rapidly analyze images and detect defects within milliseconds, significantly accelerating the inspection process, increasing throughput, and keeping pace with high-speed manufacturing lines without compromising accuracy.

05.

Regulatory Compliance

AI-powered inspection systems provide detailed records, traceability, and standardized quality checks, helping manufacturers meet industry regulations, pass audits efficiently, and ensure products consistently adhere to safety and compliance standards.

Customer Success Story

AI Powered Visual Check for Zero Waste

Saahas Zero Waste Management is the provider of end-to-end waste management services based on circular economy principles. While suppliers supply waste materials, it is challenging to segregate the waste materials according to the recycling category. Fogwing Vision…

Learn More

BLOG

How Visual Inspection helps in Quality Control?

Visual Inspection in Quality Control (QC) is a process in which products or materials are examined and assessed using visual means to ensure they meet specified quality standards….

Quality Inspection FAQs

The most common questions are answered.

Visual quality inspection in manufacturing examines products or components to ensure they meet predefined quality standards by identifying defects such as surface scratches, dents, cracks, color inconsistencies, misalignments, or missing parts.

This inspection can be carried out manually by human inspectors or automatically using machine vision systems equipped with cameras and image processing software. Manual inspection relies on trained personnel’s visual judgment and experience, which can be limited by human fatigue and subjectivity.

In contrast, automated visual inspection offers a faster, more accurate, and consistent quality control method by using high-resolution imaging and artificial intelligence to detect even minute defects in real time.

This technology is widely used across automotive, electronics, packaging, and food processing industries to maintain high product standards, reduce waste, and enhance customer satisfaction.

By integrating automated visual inspection into the production line, manufacturers can ensure continuous quality monitoring, reduce human error, and make data-driven decisions to improve operational efficiency.

In quality inspection, an AI-powered system enhances accuracy, speed, and consistency in detecting product defects. AI systems use machine learning and computer vision algorithms to analyze images or video streams from cameras to identify flaws such as cracks, misalignments, or color variations.

These systems learn from large datasets of good and defective samples, improving over time with minimal human intervention.

AI-powered inspection can detect subtle defects that human eyes might miss and operate continuously without fatigue.

It also enables real-time alerts, predictive maintenance, and integration with manufacturing systems, resulting in improved product quality

AI-powered quality inspection implementation requires installing high-resolution cameras on the production line, collecting image data, and training machine learning models to detect defects.

Integrate the AI system with inspection software for real-time analysis, connect it to production systems, and continuously refine the model with new data for improved accuracy.