Best Preventive Maintenance Software

Automate Preventive Maintenance for Maximize Asset Reliability and Uptime

Fogwing Preventive Maintenance Software automates preventive maintenance from planning to work execution, eliminating manual entry and missed maintenance. Fogwing delivers higher asset reliability, lower downtime, and operational excellence.

Minimize downtime with Preventive Maintenance Software

Industrial-Grade Preventive Maintenance. Engineered for Control, Compliance, and Asset Reliability.

Preventive Maintenance Schedule

Automate Preventive Maintenance with Ease

Fogwing Preventive Maintenance Software simplifies preventive maintenance automation without compromising operational control. Maintenance plans are configured once at the asset or asset-class level, and Fogwing automatically generates, assigns, and tracks preventive work orders based on defined rules, eliminating manual scheduling and follow-ups.

- Once triggered, Fogwing automatically creates preventive maintenance work orders.

- Assigns them based on asset, team skill, and shift rules

- Reserves required spare parts required for maintenance

- Set predefined scope through checklists

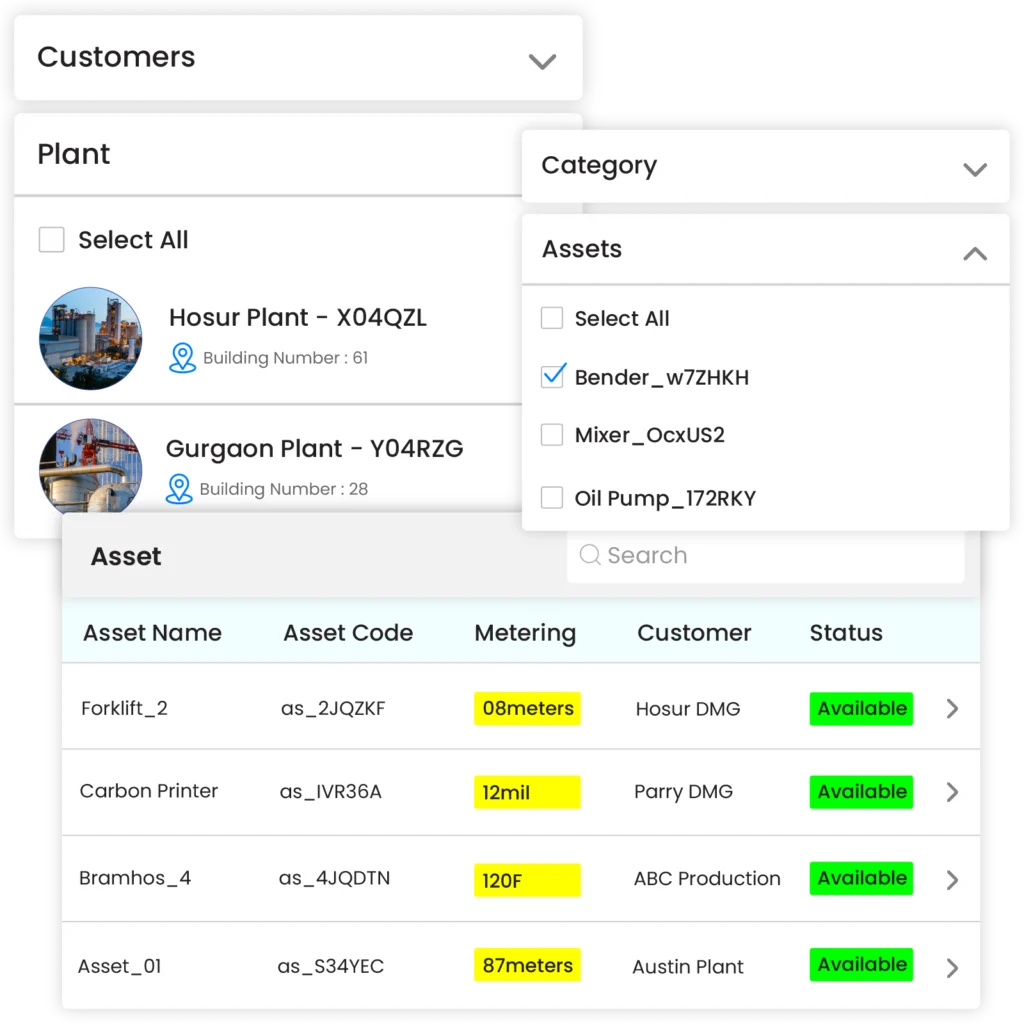

Asset Based Preventive Maintenance

Asset-Centric Preventive Maintenance by Design

Preventive maintenance strategies are defined directly at the asset level, ensuring each machine or equipment is maintained based on its criticality, operating conditions, and risk to production.

- Build multi-level asset hierarchies as location, category, parent and child basis.

- Classify assets by criticality, risk, and compliance impact

- Assign preventive maintenance strategies per asset or asset category

- Define maintenance responsibility and team requirements as per asset criticality

Asset Condition-Based Preventive Maintenance

Prevent Downtime with Condition-Based Preventive Maintenance

Fogwing enables preventive maintenance to be triggered by actual asset conditions. By integrating IoT data such as vibration, temperature, pressure, runtime, and energy parameters, Fogwing allows maintenance teams to initiate preventive work orders when operating thresholds or abnormal patterns are detected.

Fogwing integrates with industrial IoT and edge systems to enhance preventive strategies.

- Live monitoring of vibration, temperature, pressure, current, and energy

- Automatic PM triggers when thresholds are breached

- Reduced unnecessary routine inspections

- Better alignment between asset condition and maintenance action

Preventive Maintenance Governance

Get Performance Reports and Set Governance

Fogwing provides management-grade visibility through real-time dashboards and structured reports that track key metrics such as preventive maintenance compliance and assess the effectiveness of preventive maintenance strategies.

Fogwing provides management-grade visibility into preventive maintenance effectiveness.

- Creating Preventive Maintenance Compliance Reports is simplified.

- Every preventive task is traceable from planning to execution

- Get comparison chart for cost of preventive vs corrective maintenance

- Asset reliability indicators (MTBF, failure trends) and health score indicates the maintenance effectiveness

Fogwing CMMS for Preventive Maintenance

Why Maintenance Teams Choose Fogwing for Preventive Maintenance

In Fogwing, preventive maintenance software is not just a reminder tool, but rather a controlled operational system that applies preventive maintenance best practices.

- Maintenance tasks are generated automatically based on defined rules

- Maintenance plans are mandatory for critical assets

- Execution follows approved SOPs and checklists

- Maintenance progress are visible, escalated, and auditable

- Preventive maintenance becomes repeatable, measurable, and enforceable.

FAQs about Preventive Maintenance software

Fogwing Preventive Maintenance Software is a CMMS Software that helps organizations plan, schedule, execute, and track maintenance activities before equipment failures occur. It automates recurring maintenance tasks based on time, usage, or asset condition to improve reliability, reduce downtime, and extend asset life.

Fogwing Preventive Maintenance Software ensures maintenance tasks are performed consistently and on time using automated schedules, standardized checklists, and execution controls. By preventing missed inspections and delayed servicing, it reduces unexpected failures and improves overall asset reliability and uptime.

Reactive maintenance fixes equipment only after it fails, often causing unplanned downtime and higher costs. Preventive maintenance focuses on maintaining assets proactively at planned intervals to avoid breakdowns, improve safety, and reduce emergency repairs.

Yes. By automating maintenance schedules, enforcing task completion, and identifying early warning signs, Fogwing Preventive Maintenance Software significantly reduces unplanned downtime and production disruptions.

Fogwing Preventive Maintenance Software supports condition-based maintenance by integrating with IoT sensors and asset condition data such as vibration, temperature, and runtime. Maintenance tasks are triggered only when predefined thresholds are reached, reducing unnecessary maintenance.

Get Started with Fogwing CMMS Today!

No Credit Card Required. Open Your Account Now.