Manufacturing industries rely heavily on automation machinery and equipment for daily productivity. Any machine downtime during production will have a financial impact due to non-productive work hours, quality degradation, and

Empower your maintenance efficiency with Industrial AI-assisted maintenance software: Unleash the Power of data intelligence and save 80% of redundant maintenance efforts.

The state-of-the-art Art Industrial AI assistant powered by Generative AI technology. Our ground-breaking technology empowers maintenance operations team and sets the stage for a transformative future in maintenance management.

Revolutionize your maintenance workflow: Seamlessly generate maintenance checklists for every asset or asset category using Generative AI technology, establish standard operating procedures, and achieve maintenance excellence with Fogwing Asset+ maintenance software.

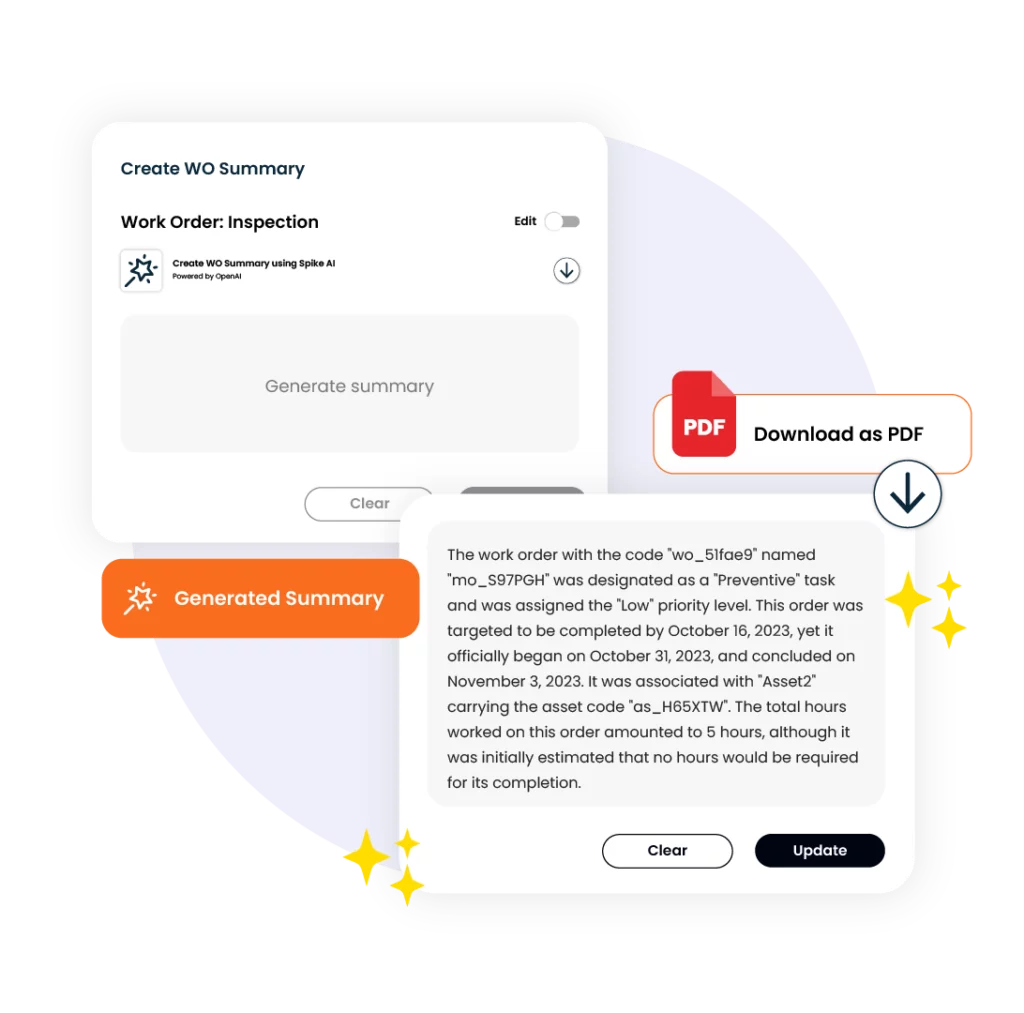

Instantly generate comprehensive summaries and reports. Effortlessly compile detailed maintenance summaries and reports with our cutting-edge solution. Save time, boost productivity, and stay ahead of maintenance schedules. Try it now and experience the convenience firsthand. Streamline Your Maintenance Workflow.

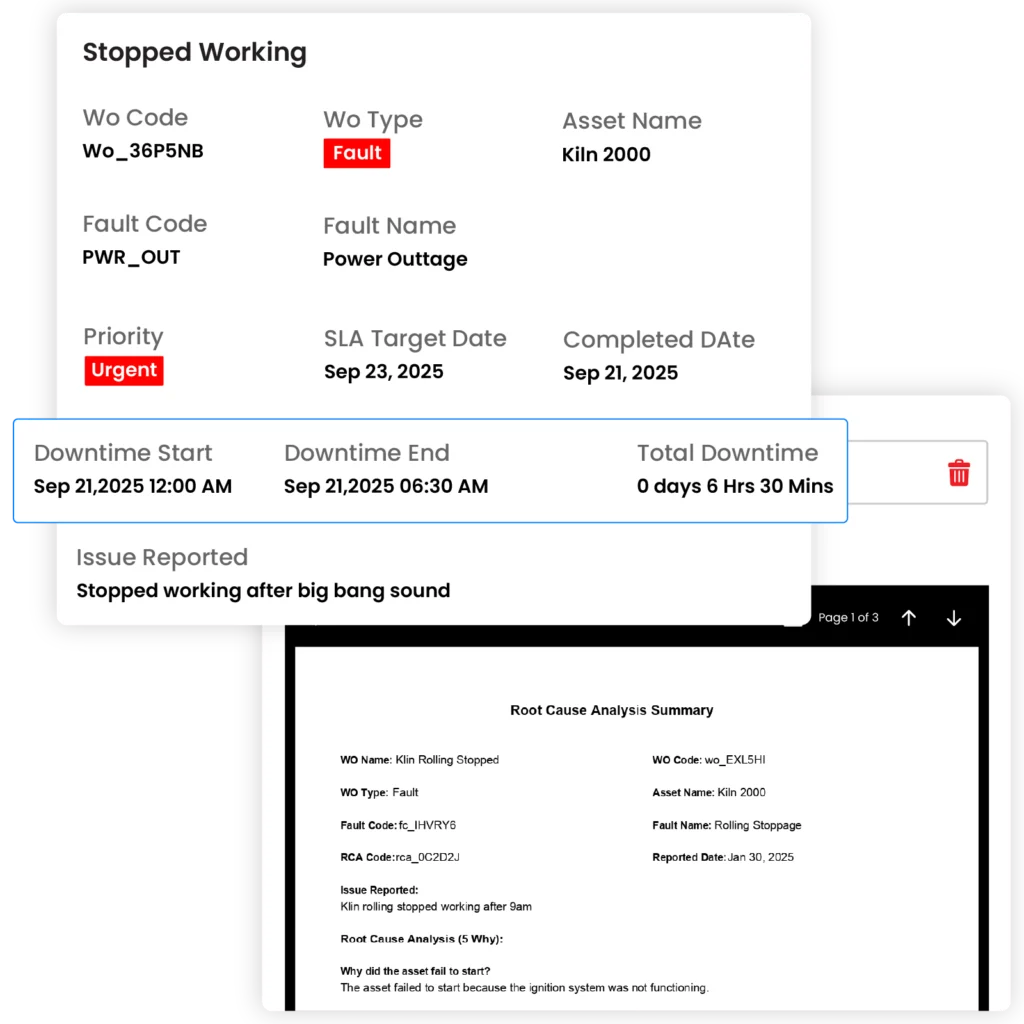

Fogwing’s AI-powered Maintenance Software leverages advanced generative AI technologies to identify the root cause analysis with 5-why methodology to identify patterns behind repeated equipment failures.

It pinpoints underlying issues using historical and real-time data, then recommends corrective actions to prevent recurrence. This enables maintenance teams to resolve persistent problems efficiently, improving asset reliability and reducing unplanned downtime.

Proactively detect and prevent asset failures automatically. Our innovative solution employs advanced algorithms to anticipate potential failures, allowing you to take preventive action before they occur. Say goodbye to costly downtime and unexpected disruptions. Embrace proactive asset management and safeguard your operations with ease

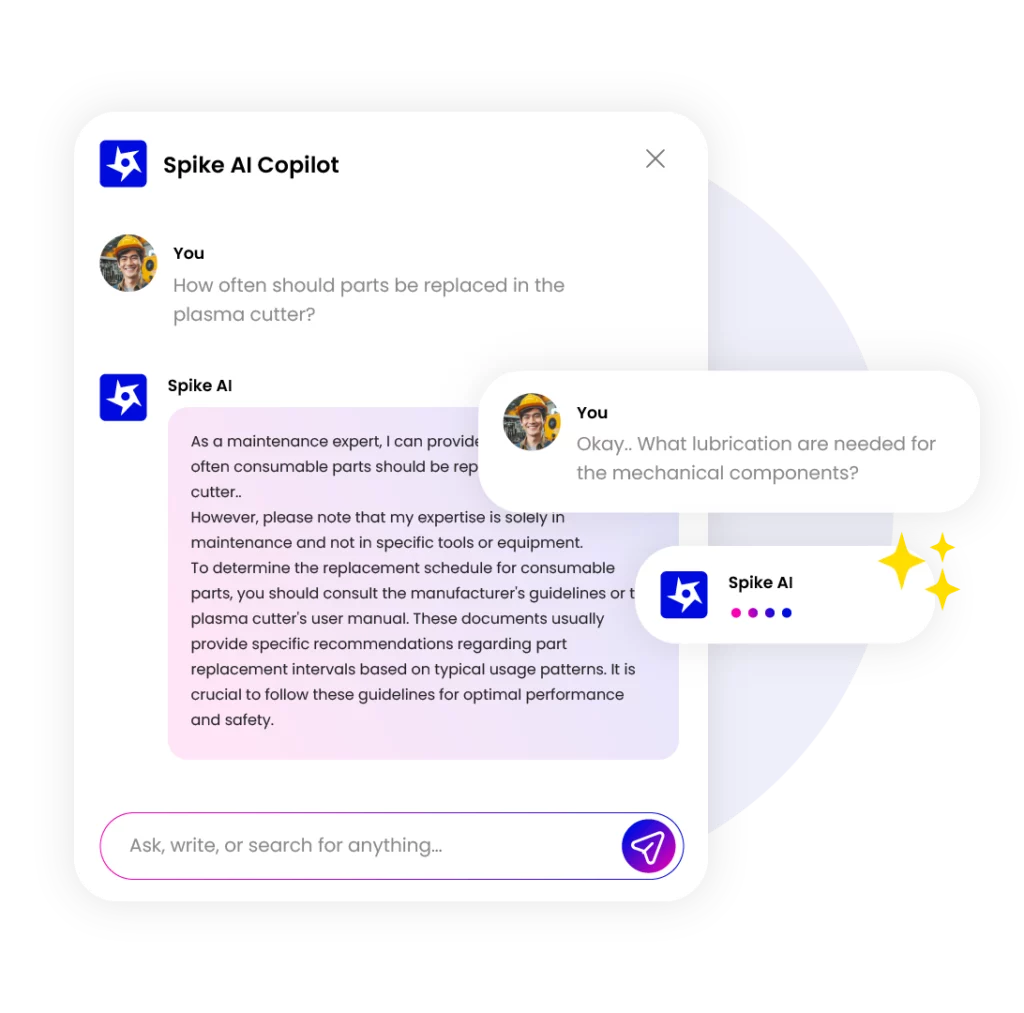

Boost your productivity with AI Copilot Assistance! Integrated into the app, our advanced OpenAI Chatbot offers real-time support, personalized suggestions, and streamlined assistance, empowering you to accomplish tasks more efficiently. Upgrade now to experience the future of collaboration!

AI-powered maintenance software leverage advanced AI technologies to help maintenance team to optimize daily asset maintenance operations.

This software application helps to analyze the historical maintenance records to come up with a recommendation for optimal maintenance actions to prevent guess work.

AI-powered maintenance software also provides capabilities to detect asset anomalies and forecasting issues before it occur.

These forecasting helps to predictive and prescriptive maintenance actions, work procedure to reducing repetative downtime and maintenance costs.

Industria AI copilot enabled maintenance software such as Fogwing CMMS provides technical assistance to the field engineers to guide at real-time based on equipment specification and history of failure.

Overall, AI-powered maintenance software helps prioritize maintenance tasks, improve resource allocation, and extend asset lifespan.

AI is used in maintenance to optimize equipment performance and prevent downtime. Predictive maintenance analyzes historical data and sensor readings to forecast potential failures, allowing preemptive repairs. Machine learning algorithms detect patterns indicative of malfunction, enabling timely interventions and minimizing costly breakdowns.

AI also facilitates condition-based maintenance, where equipment health is continuously monitored, and maintenance is scheduled based on real-time performance metrics. This proactive approach reduces maintenance costs, extends equipment lifespan, and ensures uninterrupted operations. Overall, AI-driven maintenance strategies enhance reliability, efficiency, and productivity across various industries, from manufacturing to transportation and beyond.

AI in maintenance offers numerous benefits, including enhanced equipment reliability and uptime through predictive maintenance, minimizing unplanned downtime and associated costs. It optimizes maintenance schedules, reducing unnecessary inspections and replacements while extending equipment lifespan. AI-driven analytics provide deeper insights into asset health and performance, enabling data-driven decision-making and resource allocation. Additionally, it enhances safety by identifying potential hazards and recommending preventive measures. Improved operational efficiency and productivity result from streamlined maintenance processes and optimized resource utilization. Ultimately, AI empowers organizations to transition from reactive to proactive maintenance approaches, fostering a more sustainable and competitive operational environment.

Anomaly detection is a technique used in data analysis to identify patterns that deviate from expected behavior within a dataset. It involves detecting outliers, unusual patterns, or abnormalities that may indicate potential problems, errors, or opportunities for further investigation, particularly valuable in predictive maintenance, fraud detection, and cybersecurity.

Manufacturing industries rely heavily on automation machinery and equipment for daily productivity. Any machine downtime during production will have a financial impact due to non-productive work hours, quality degradation, and

Due to industrialization and infrastructure expansion in the Middle East, the region is experiencing fast growth in its oil & gas, construction, logistics, utilities, and manufacturing, enabling it to embrace

In today’s fast-paced industrial landscape, maintenance professionals are often bogged down by traditional maintenance management practices like reactive maintenance, manual entry, miscommunication, and unexpected downtime. Industry maintenance management inefficiencies drain